Plastic blow moulding faces ever increasing challenges for the production of more sustainable plastic containers.

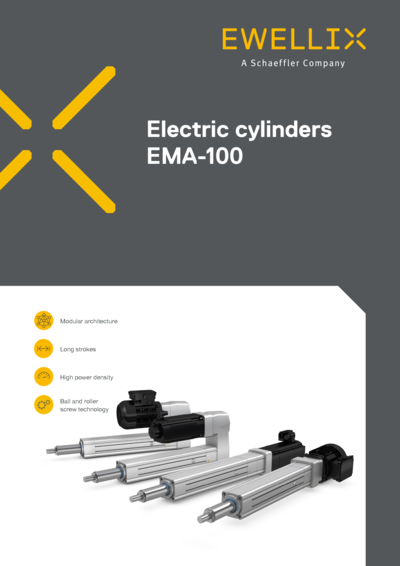

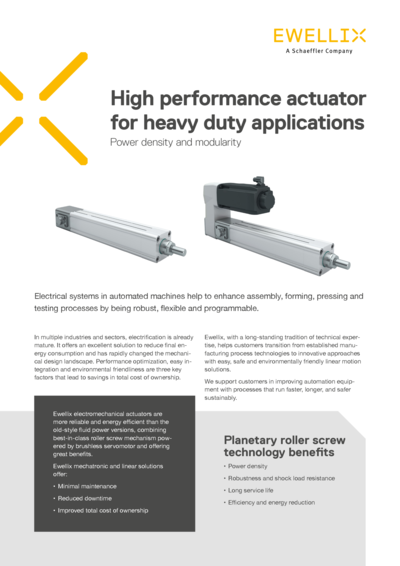

EMA-100 (old CASM-100)

Benefits

- Suitable for a wide range of applications with different power requirements and operating life

- Long service life despite very high loads

- Accurate positioning (based on motor feedback system)

- High level of flexibility in the mounting cylinders, in place of hydraulic ones

Features

- Standardised and highly adaptable interfaces, with roller screws or ball screws

- Parallel gearboxes with gear wheels and manual controls, wide range of accessories

- High level of accuracy and repeatability

- Standard range, up to 2 metres

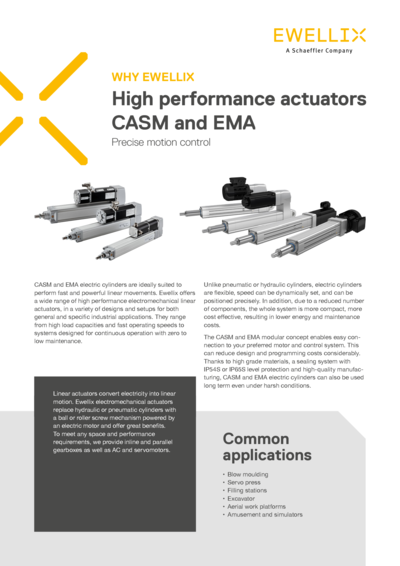

Ewellix developed an innovative modular electric cylinder platform to address most of the applications in the automation and heavy machinery industries, mainly replacing hydraulic solutions. In this new design, the modularity has been extended to the base component level. Within each module, the customer can select the components inside to build a custom-like solution as standard with the best performance/cost ratio.

To meet any space and performance requirements, Ewellix provides inline and parallel gearboxes as well as AC and Servomotors. Its modular concept enables easy connection to any preferred motor and control system, reducing design and programming costs considerably.

To meet any space and performance requirements, Ewellix provides inline and parallel gearboxes as well as AC and Servomotors. Its modular concept enables easy connection to any preferred motor and control system, reducing design and programming costs considerably.

e-MOVEKIT

To make integration into any system as simple and smooth as possible, Ewellix provides the motor control options e-MOVEKIT, the plug-and-play electrification kit for linear movements in mobile machinery.

Technical Data

Overview

| Max stroke (mm) |

2 000 |

|---|---|

| Operating temperature | |

| Type of protection |

IP 54 |

| Max. linear speed no load (mm/s) |

890 |

| Max. dynamic axial force (kN) |

82 |

| Dynamic load capacity (kN) |

106 |

| Screw type / Diameter Lead (mm) |

Ball screws or roller screws, 32x10, 40x10, 40x20, 30x10 |

| Motor type |

Servo motor, AC motor |

| Duty cycle (%) |

100 |

2D / 3D

Publications

Frequently asked questions

An electromechanical actuator is a motion control device that converts electrical energy into precise mechanical movement. It typically consists of an electric motor (AC, DC, Brushless DC or servomotor), a mechanical transmission system such as a screw drive, and optional feedback elements for position control. These actuators are known for their accuracy, repeatability, and long service life. They are widely used in applications requiring controlled linear motion, such as industrial automation, robotics, and mobile equipment, especially where integration with electronic control systems is important.

Hydraulic actuators utilize pressurized fluid for motion, excelling in high-force applications and demanding environments. However, they come with significant drawbacks: complex infrastructure, frequent maintenance needs, fluid leakage risks, and most notably, poor energy efficiency. They constantly consume power to maintain fluid pressure, even when idle, leading to substantial energy waste. In contrast, electromechanical actuators convert electrical energy into mechanical motion, typically via electric motors driving ball or roller screws. They offer superior energy efficiency by consuming power only on demand—when actively moving or holding a load—eliminating the continuous energy drain of hydraulic systems. This translates to significantly lower operating costs and a reduced carbon footprint. Beyond efficiency, they also provide higher positioning accuracy, cleaner operation, and seamless integration with digital control systems. Consequently, electromechanical actuators are increasingly replacing hydraulic systems in automation and mobile machinery due to their overall performance advantages.

A modular actuator is an actuator system designed with interchangeable and configurable components, allowing for tailored solutions without the need for full custom engineering. Key elements such as screw types, gearbox orientation (inline or parallel), motor type, and mounting interfaces can be selected independently to match specific space constraints, load requirements, and control preferences. This modularity offers flexibility, simplifies system integration, reduces engineering time, and enables easy future upgrades or reconfigurations using standard components.

Need more

information?

Ask our experts.